New hydrogen test facility

Evoenergy and the Canberra Institute of Technology (CIT) have partnered to build a first-of-its-kind dedicated hydrogen test facility to understand how hydrogen gas could be used in the future to power homes using the existing natural gas network.

The facility will test materials, equipment and work practices, with the view to using hydrogen in the existing gas distribution network in the future.

Opening the facility in Canberra this week, ACT Minister for Climate Change, Shane Rattenbury MLA, said renewable hydrogen gas could have potential as a zero-emissions replacement for natural gas.

The use of hydrogen as a household energy resource aligns with the ‘green energy’ targets set by the ACT Government, including reaching 100 per cent renewable electricity by 2020 and reducing emissions to zero by 2045.

‘‘Hydrogen can be a renewable, zero-emissions gas source, and we want to understand whether, and how, it can be viably used to decarbonise the gas network,” Mr Rattenbury said.[1]

Hydrogen is carbon-free and can be produced from excess renewable energy, for example during sunny and windy days when generation is high and demand is low. It offers a stable, carbon-free energy resource that can be stored for use on demand

‘Hydrogen has the potential to both expand the usage of renewables across the day, but also bring the price down.’

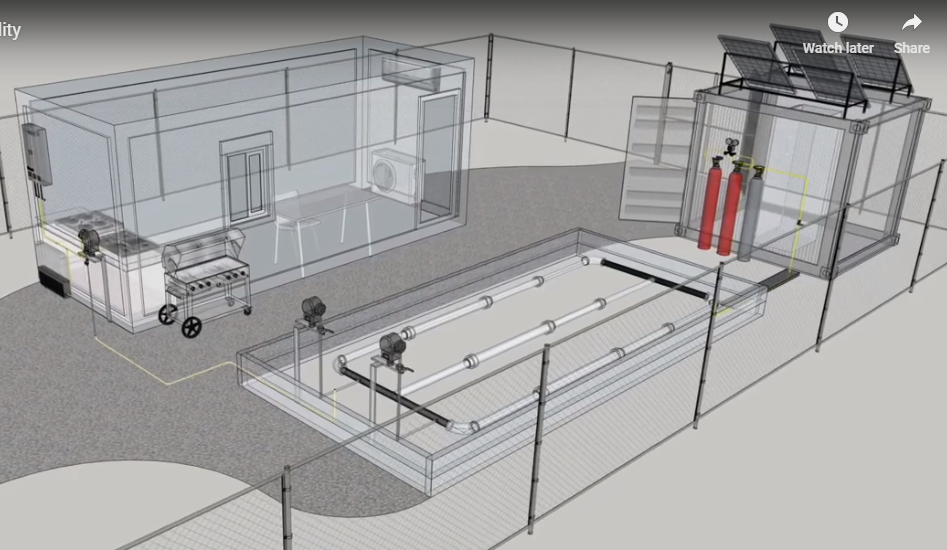

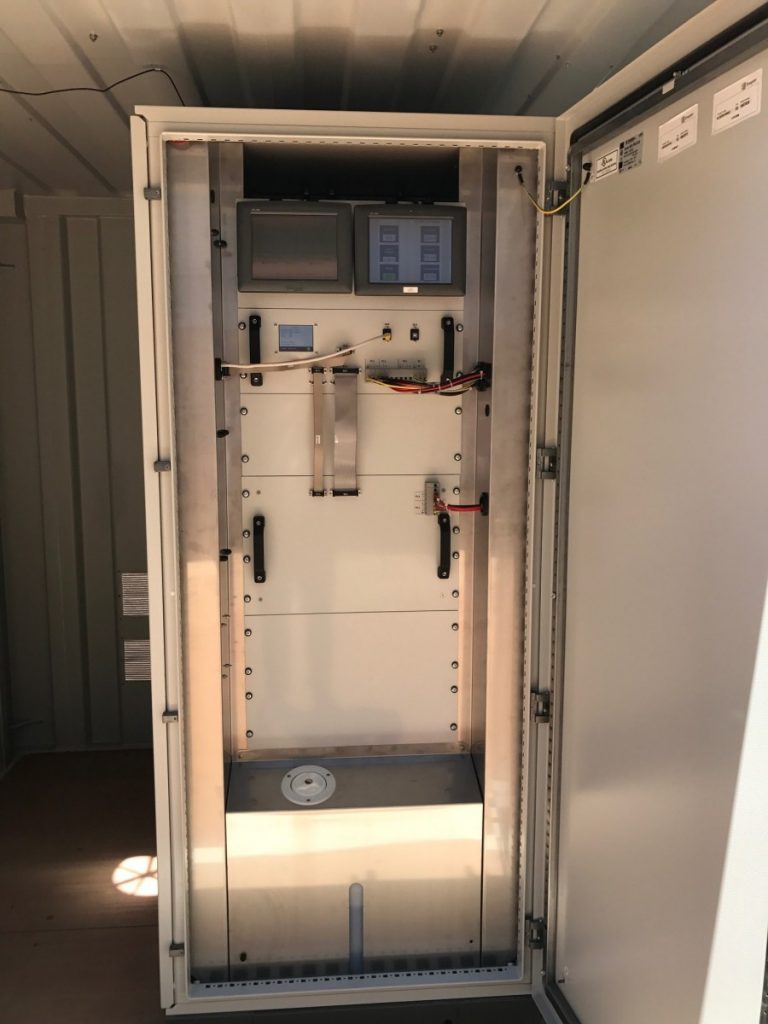

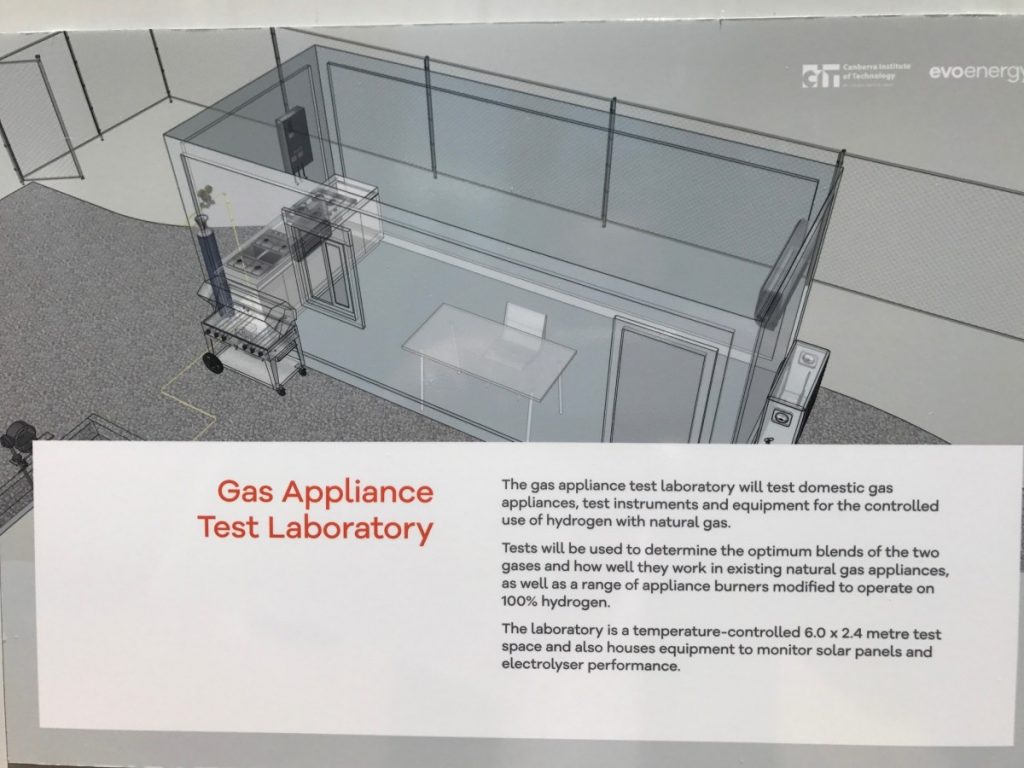

The facility will provide key learnings to assist the transition to using hydrogen in gas networks. The facility has a number of different zones, a hydrogen production and storage zone, a network testing zone and an appliance testing zone. Work will be carried out in three phases over the next yearacross all three zones.

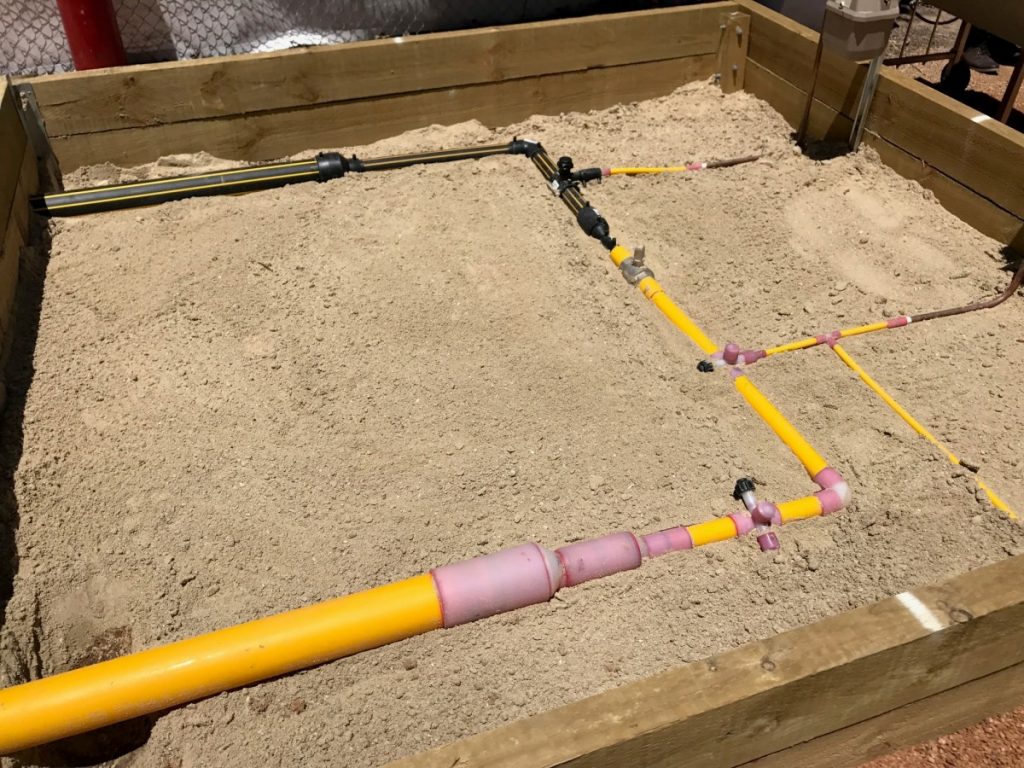

Phase 1:

The first phase replicates the materials used in existing gas networks and will help us better understand how the current components, construction and maintenance practices can be applied to a network that is converted to hydrogen. The network materials used include nylon and polyethylene components across a range of sizes that are commonly used across Evoenergy’s gas network.

Phase 2:

Hydrogen will be produced from solar PV to complement hydrogen supplied from cylinders. An electrolyser cell connected to solar PV panels will produce renewable hydrogen and this will then be stored before being used in the facility. The performance of hydrogen production will be tested with variable and intermittent solar PV to better understand how electrolysers can be used with excess renewable energy to help provide stability to the electricity grid. Once deployed at scale, this creates an added advantage of being able to generate hydrogen from excess renewables in summer, storing that in the gas network and using it at a later time.

Phase 3:

Hydrogen is a different fuel to natural gas and changing the gas composition to include hydrogen may result in appliances not performing as they were designed to. The third phase will improve understanding of how hydrogen mixtures and pure hydrogen will perform in appliances. Common appliances to be tested include a cooktop, an instantaneous hot water system and a portable gas heater. Both compositions of hydrogen in gas (eg 10 per cent by volume) and pure hydrogen will be tested. Some burner modification will be tested with 100 per cent hydrogen.

The outcomes from this work will be to identify the level of hydrogen substitution can be carried out while ensuring the safety and performance of appliances. A much broader program of appliance testing will need to be carried out to cover the broad range of gas appliances across the country.

Video: Evoenergy launches Australia’s first hydrogen test facility.

Bioenergy Australia

Earlier in the day, Bioenergy Australia launched its Bioenergy State of Play report[2] followed by a barbeque using biogas.

Of particular interest was the difference from a normal gas cylinder. As biogas is mostly methane, it is compressed to high pressure and stored in a cylinder. When required, a couple of pressure regulators reduce the pressure to a safe level so that it can be used in a barbeque. A typical gas cylinder for a barbeque uses propane but liquefies that so that it does not require the same pressure.

The biogas used in the barbeque was produced from organic waste material, which is essentially solar energy converted to plant material and harvested recently.

The launch also highlighted the potential role of biodiesel and biogas as a transport fuel.

Technology neutrality

It is encouraging to see renewable gas being used – two completely different gases used on two separate occasions. It clearly demonstrates a broad range of innovation being carried out by industry and highlights the many different opportunities being created to use renewable gas.

Policy options should encourage further innovation without specifying preferred technologies.

Ongoing support to RD&D

The hydrogen and biogas work will complement the Future Fuels Cooperative Research Centre (CRC), which will be doing more broad-reaching research on network materials, appliance performance and the integration of hydrogen into the energy system over the next seven years.

The Future Fuels CRC will also undertake a broad community engagement program to better understand how the community will respond to the proposed changes to renewable gas.